For businesses or store operators, handbags are not only packaging, but also a way of brand promotion. There are many types and materials of handbags. Let’s learn about them together!

Types of handbags:

Advertising handbags: Advertising handbags use visual effects to convey their design. They pay more attention to the promotion and development of advertising, and design the name and slogan of their own company or store on the handbag.

Knowledge handbags: Knowledge handbags are all kinds of patterns and words with certain knowledge, such as world famous paintings, Chinese calligraphy, etc., printed on shopping bags.

Gift handbags: Gift handbags are designed in the form of handbags to increase the value of gifts and make it convenient to carry gifts. They have gorgeous and beautiful graphics, and it is very good to put gifts inside.

Antique handbags: Antique handbags are often made of exquisite materials and sophisticated production. And when the shopping bag is printed with simple and elegant patterns and words, its retro feel will attract many customers.

Decorative handbags: Decorative handbags have no specific functions. They are used to carry personal belongings and are fashionable decorations.

Commemorative handbags: Commemorative handbags are commonly specially designed and made to commemorate a certain cultural and artistic activity. This strategy caters to people's commemorative and honorary psychology. Such bags are generally printed with the name, logo, explanatory text, etc. of the event.

Handbag Material

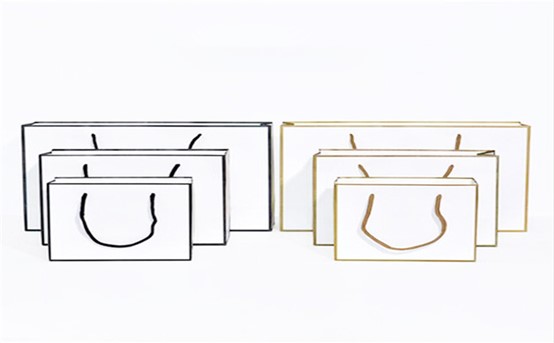

White cardboard: A handbag made of white cardboard is the most high-end handbag. Its strength is the highest among all handbags, which is determined by the physical properties of white cardboard. This kind of handbag is generally used to hold high-end clothing or goods. Compared with white board paper handbags, white cardboard handbags have a more delicate feel, so white cardboard handbags look particularly elegant.

Kraft paper:Kraft Paper Bags are strong and cheap, and are generally used to hold ordinary goods. Except for white kraft paper, the base color of kraft paper is generally darker, so it is more suitable for printing dark text and lines, and can also design some contrasting color blocks. Kraft paper bags are generally not coated and are the cheapest bags.

How to choose the printing process for handbags

Common processing techniques for handbags include hot stamping, hot silver stamping, embossing, UV, glossy film or matte film. The processing technology can highlight the design theme, the surface color of the paper is bright, the texture grade is increased, and the feel and sense are improved. And the pattern is clear and the finishing touch is added. In order to prevent the paper from yellowing, fading and breaking, some also need to make transparent plates so that the internal products can be seen.

Handbag printing process

Design and material selection

The design and production of paper bags is the key link of the entire paper bag production process. Most paper bags are an extension of corporate image and product advertising strategies, so the materials selected, the decoration process and the form of expression are inseparable from the purpose and function of the paper bag.

Kraft paper has good toughness, high strength and a rough surface. Cardboard has good stiffness but poor toughness, and generally requires surface coating when used as a paper bag. Coated paper has a certain toughness and rich printing colors, but its stiffness is worse than cardboard. When emphasizing durability, kraft paper is often used. When both color and stiffness are important, cardboard is mostly used. When rich and gorgeous pattern effects are required, people often prefer white cardboard. In order to improve the taste and grade of handbags, designers have put a lot of thought into the post-printing surface decoration process.

The flexible use of hot stamping, UV, glazing, colorful, embossing and flocking processes also makes the paper bag bright in color, enhanced in three-dimensional sense, and richer in expression. Of course, no matter what finishing process is used, designers should consider the economic utilization of paper materials and the rationality of process design.

Handbag lamination

Lamination, also known as post-printing lamination, post-printing gluing or post-printing filming, refers to a post-printing finishing process that covers the surface of the printed product with a layer of 0.012-0.020mm thick transparent plastic film to form a paper-plastic integration process. It is generally divided into two processes: pre-coating and instant coating. According to the different film materials used, there are high-gloss films and matte films. With the use of environmentally friendly water-based solvents, the environmental friendliness of the lamination process has been further improved.

Non-kraft paper bags mostly use lamination technology, mainly because lamination can increase the concentration of color, the product has good waterproof and anti-fouling properties, and the physical properties of paper such as anti-aging, tearing and puncture resistance are generally improved, thereby improving the fastness and strength of paper bags, and significantly enhancing the carrying capacity. In particular, the use of matte film can give people a soft and feeling.

Surface finishing Hot stamping, UV, glazing and other printed surface finishing processes are widely used production processes for handbags. It greatly satisfies people's pursuit of paper bags. In the production process, the key points in these process links must also be controlled. Compared with gold printing, the hot stamping process has a stronger metallic feel, better consistency, brighter color, and richer three-dimensional sense. A good hot stamping effect depends on the organic coordination of the temperature, pressure and speed of hot stamping.

Die-cutting process The die-cutting process is a process method in which the die-cutting knife and the creasing knife are combined on the same template and the die-cutting machine is used to die-cut and creasing the printed product, also known as "rolling marks". It is an important process in the production process of paper bags. The quality of die-cutting directly affects the quality of paper bag forming and the efficiency of manual pasting.

The pasting process of box pasting is a special link in the production of portable paper bags. In addition to the auxiliary use of some semi-automatic equipment, it mainly relies on manual completion, which is an inefficient link in the entire paper bag process. Developed countries have a particularly huge demand for exquisite portable paper bags, because they cannot be completed through automated production lines.

Of course, the first piece of paper bag pasting before mass production can refer to the process planning during proofing for process re-evaluation. The hand-pasted paper bags are basically formed. Some paper bags have a final process - punching, threading and other operations to complete the final packaging of the paper bags.

Contact: Zora Cai

Phone: +86-18036809719

E-mail: admin@ryyin.com

Add: Building 12, Standard Factory Building, Hailing Industrial Park, HailingDistrict, Taizhou City, jiangsu Province